Pulsation Dampeners

The majority of pump pulsation problems can be traced to and remedied on the suction side of a pump. It is imperative to maintain a steady flow of fluid through the suction valves. Therefore, it is recommended that pulsation Stabilizers be attached to the suction side first, then the discharge Side of a pump.

- Top Ring Manufactured for Maximum Thread Engagement

- Tubular Specification ASTM A-106-5

- Model Code and Safety Information

- 396 Stainless Steel Bleeder Valve uses Needle and Seat Configuration for Positive Seal and Long Life

- All Units Internally Coated with Scotchkote 134 to a Minimum of 10 Mills Guaranteed Holiday-Free

- with a Powder-Based Polyester Coating

- ANSI Flanges A-105

Specification

We use 100 percent traceable materials and all applied engineering standards are strictly maintained.

- Threaded Heads

- Solid Steel Construction Thread Engagement

- Rated Three Times Unit Working Pressure

- Hand-Crafted, Multi-Ply Fiber-Belted Rubber, Nitrite, EDPM or TEF Encapsulated

- Inverted Bottom Plug for Maximum Gas Volume

- 2-314" Hex Nut for Safe and Easy Cartridge Installation and Removal

- Stainless Steel Dand

- 2, 4, Or 6-ply layers Polyester / Reinforced. Vulcanized with Reparation to Ensure Superior Cartridge Strength,

- Maximized Inner Diameter Promotes increased Gas Volume

Stainless Steel Band Cartridge is pre-stretched and tested with Nitrogen only. - 24 hours. Maximum Pressure.

- End-Sealed for Internal Cord Protection

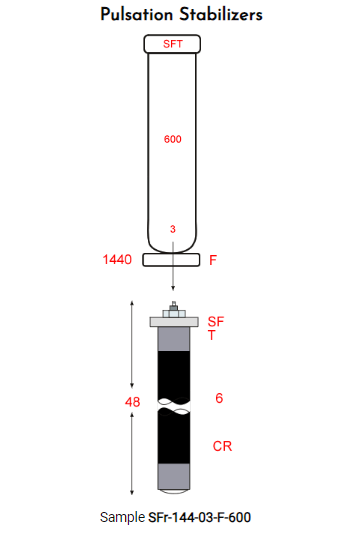

Model Code Nomenclature

Sample SFr-144-03-F-600

- Cartridge Connection Type: (SFT) Threaded; (SFU) Union Head: (SFV) Grooved Coupling; (SFVM) Grooved Coupling Magnum; (SFM) Wingnut

- Magnum Rated Operating Pressure:150, 450, 700, 1440, 2100, 3600, 5000 PSI

- Opening S Size, 1" through 8" (Depends on Series)

- Mounting Type: (F) Flange, (T) Thread

- Cubic-Inch Gas Vol ume of Stabilizer Internal Cartridge: 100, 300, 600, ,900, and 1200 Cubic inches

Sample: 5Ff-486-Cf

- Connection Type: (SFT) Threaded; (SFU) Union Head; (SFV) Grooved Coupling; (SFVM) Grooved Coupling Magnum; (SFM) Wingnut Magnum

- Cartridge Length: 18",24",36",48"

- Number of flies: 2-Ply 4-Ply, or 6-fly

- Type of Material: (CR) Nitrile, (CR F PDM) EPDM; (C R TEF) TFF

- Encapsulated

SIZING INFORMATION

In general, the majority of pump pulsation problems can be traced to and remedied on the suction side of a pump - even though some symptoms may show up on the discharge side In feeding the pump. It is imperative to maintain a steady flow of fluid through the suction valves. Also, the fluid column must attach thoroughly to the face of the plunger to achieve complete cylinder fill on the suction stroke. Therefore, it is recommended that pulsation Stabilizers be attached to the suction side first, then the discharge Side of a pump.

Pump Capacity

Determine the amount of fluid a pump will be moving, at what speed, and at what pressure. Indicators: Number of plungers, Bore, Stroke Length, RPM Suction & Discharge Pressure

Fluid Type and Temperature

Fluid that is pumped must be compatible with the internal cartridge material.

Pump Opening Types and Sizes

The pulsation Stabilizer opening Should match the opening on the side of the pump on which it will operate. This will guard against unwanted acceleration or deceleration of fluid as it passes between the pump and stabilizer Always defer to the next larger Size should an exact match not be available.

Pump System

Before installing a Status Flow pulsation stabilizer, be sure to consider the makeup of the overall system. Be aware of system characteristics that could effect a stabilizer decision such as other pumps running in line, upstream/downstream pressure considerations, fluid composition, or multiple pumps on a common header.

To size stabilizers, you will need:

- Pump Stroke Length

- Pump Connection Sizes and Types

- Suction and Discharge Pressures

- Fluid Type and Temperature

NOTE: The stabilizer opening should be the same size as the pump opening or larger. flanged and threaded Sizes are available from 1' to 8" - depending on the Series.

Replacement Cartridge

| Cartridge Model # | ply | Gas Volume | Length | Width | Weight | Max. Charge |

| SFU-182-CR | 2 | 100 cu. in. | 15" | 3" | 15 lbs. | 100 PSI |

| SFU-186-CR | 6 | 100 cu. in. | 18" | 3" | 15 lbs. | 300 PSI |

| 5FV-242-CF | 2 | 300 cu. in. | 24" | 4" | 25 lbs | 100 PSI |

| 5FV-244-CR | 4 | 300 cu. in | 24" | 4" | 30 lbs. | 300 PSI |

| SFV-482-CR | 2 | 600 cu. in. | 45" | 4" | 25 lbs | 100 PSI |

| SFV-484-CR | 4 | 600 cu. in. | 48" | 4" | 30 lbs. | 300 PSI |

| SFT-242-CR | 2 | 300 cu. in. | 24" | 4" | 25lbs. | 100 PSI |

| SFT-244-CR | 4 | 300 cu. in. | 24" | 4" | 30 lbs. | 300 PSI |

| SFT-246-CR | 6 | 300 cu. in. | 24" | 4" | 35 1bs. | 500 PSI |

| SFT-482-CR | 2 | 600 cu. in. | 48" | 4" | 25 lbs. | 100 PSI |

| SFT-484-CR | 4 | 600 cu. in. | 48" | 4" | 30 lbs. | 300 PSI |

| SFT-486-CR | 6 | 600 cu. in. | 48" | 4 | 50 lbs. | 500 PSI |

| SFVM-364-CR | 4 | 900 cu. in. | 36" | 6" | 60 lbs. | 125 PSI |

| SFVM-484-CR | 4 | 1200 cu. in. | 48" | 6" | 60 lbs. | 125 PSI |

| SFM-364-CR | 4 | 900 cu. in. | 36" | 6" | 60 1bs | 125 PSI |

| SFM-366-CR | 6 | 900 cu. in. | 36" | 6" | 60 lbs. | 300 PSI |

| SFM-484-CR | 4 | 1200 cu. in. | 48" | 6" | 60 lbs. | 125 PSI |

| SFM-486-CR | 6 | 1200 cu. In. | 45" | 6" | 68 lbs. | 300 PSI |

Nitrite (generic name) rubber is the copolymer of butadiene and acrylonitriie. Trade names include Hycar, Chemigum, Paracril, Krynac and NY syn, Nitrite rubbers are highly resistant to non-polar oils and solvents but are swelled or dissolved by highly polar solvents. Vulcanizates are resistant to petroleum oils and fuels and essentially unaffected by alkaline solutions, salt solutions, aliphatic hydrocarbons, dilute acids, fatty acids and vegetable fats. They are swelled and attacked strongly by ketones, aromatics and concentrated oxidizing acids. Nitrite rubbers are resistant to crude oil, gasoline, fuel and petroleum based oils but are affected by acetone, amines, toluene, benzene and related compounds. Nitrite rubbers are molded at temperatures of 300 degrees Fahrenheit and above and are generally considered serviceable up to 250 degrees Fahrenheit. However, the usable life of cartridges made of Nitrite will be shortened substantially in continuous services above 150 degrees Fahrenheit.

EPDM (generic name) is a terpolymer of ethylene, propylene and diene. Tradenames include Epsyn, Nordel, Vistalon, Epcar and Royalene. EPDM rubbers have outstanding resistance to oxygen, ozone, and heat. Vulcanizates are essentially unaffected by water, alkalines, some asides and diesters - they have poor to good resistance to aliphatic hydro carbons. They are swelled and attacked by aromatic hydrocarbons, halogenated hydrocarbons, some alcohols and vegetable and animal oils. EPDM rubbers have fair to good resistance to heavy crude oil, acetone, amines, carbonic acid, detergents, ethylene glycol and 20% hydrochloric acid but are affected by butane, propane, benzene, concentrated hydrochloric and sulfuric acid. EPDM rubbers arc Formally molded at temperatures up to 350 degrees Fahrenheit: and are generally considered serviceable up to 300-350 degrees Fahrenheit. However, the usable life of cartridges made of EPDM will be shortened substantially in continuous service above 180 degrees Fahrenheit.

Chemical reactors occur more rapidly as temperatures increase. So, a cartridge that is attacked only slightly by a fluid at atmospheric temperature may have a shortened life at higher temperatures.